Aluminothermic Welding Kit for Rail Tracks

High-strength rail welding kit for railways, metros, mining lines, and industrial tracks

Glory Track supplies complete aluminothermic welding kits designed for fast, reliable, and high-strength rail joints. Our kits support major rail standards such as UIC, AREMA, ASCE, and GB, making them suitable for global rail projects. Each set includes all tools, moulds, and consumables needed for efficient rail thermite welding in the field.

These kits help teams finish joints quickly, reduce downtime, and keep tracks running safely—whether the work is on mainline railways, metro lines, crane tracks, or heavy-haul mining routes.

Key Features & Benefits

Strong and lasting joints meeting UIC / AREMA / EN / GB standards

Fast operation with fewer tools required on-site

Good electrical conductivity and stable performance

Reliable under heavy traffic and harsh track conditions

Compatible with UIC60, 54E1, 60E2, 115RE, 136RE, ASCE rails

Cost-effective, easy to transport, and simple to operate

Custom moulds and welding portions available for special projects

What’s Included in an Aluminothermic Welding Kit

A complete aluminothermic welding kit comes with all the tools and consumables needed for on-site rail welding. Each item supports a specific step in the process, from preparing the rail ends to casting and finishing the weld. A standard kit typically includes:

Bow Card

High Temperature matches

Rail Cutter

Slug Removal Srick

Crucible Bracket

Oxygen Flow Meter

Rail Girder

Thermite

Crubiber Cover

Preheater, Preheater rack, Preheater Nozzle

Sealing Sand

Timing Stopwatch

Disposable Crucible

Propane Pressure Reducer

Slag Receving Hooper

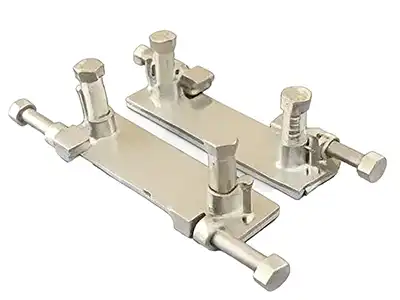

Rail Alignment Device

Welding Sand Frame

How Aluminothermic Rail Welding Works

Aluminothermic rail welding (also known as thermite welding) forms a permanent, high-strength joint by using the exothermic reaction between aluminum powder and iron oxide. The reaction generates molten steel, which flows into a sealed mould around the rail ends, fusing them into a continuous track after cooling. This process is widely used in railway, metro, and industrial track projects thanks to its reliability and minimal equipment requirements.

Step-by-Step Welding Process

- Align the rails

Position and correct the rail ends to make sure they sit in the right geometry. - Set the rail gap

Adjust the required gap for the aluminothermic welding process. - Clean the rail ends

Remove rust, dirt, and oil to ensure proper bonding. - Install the mould

Clamp the sand mould around the rail ends and seal it with sealing sand. - Preheat

Use the preheater to heat the rail ends and mould to the required temperature. - Prepare the crucible

Mount and preheat the disposable crucible on the bracket. - Ignite the thermite

Light the thermite portion; molten steel forms inside the crucible. - Pour the molten steel

The molten steel flows into the mould and fills the rail gap. - Cool and remove slag

Let the weld cool, then remove slag and trim the joint. - Finish the weld

Grind the rail head to restore the running profile.

Key Parameters of the Thermites

| Item | Iron III DE series | QU series |

| Purposes | Suitable for U75V material, also for welding of U71Mn and U76NbRE steel rails | |

| Process used | Iron III DE series and QU series thermite welding process | |

| Pouring methods | One-off crucible self-melting, side top pouring | |

| Reserved rail gap | 26±2mm | |

| Weld hardness | Hot rolled rails: P±20 | |

| Tensile strength | 880Mpa rails; Rm≥710MPa / 980Mpa rails: Rm≥780MPa | |

Why Choose Glory Track?

With extensive rail product experience, Glory Track supports railway contractors, steel mills, metro operators, and engineering firms worldwide. Our kits deliver:

- Durable & Stable: High-grade steel provides strength and long-lasting stability.

- Full traceability for consumables and tools

- Fast production and global shipping

- From mainline welding to crane track maintenance, our aluminothermic welding kits help teams work faster and safer.

Request Your Aluminothermic Welding Kit

Tell us your rail standard, rail size, and welding specification. We’ll recommend the right aluminothermic welding kit and provide a quick quote.