MK7 Continuous Rail Pad

The MK7 Continuous Rail Pad is designed for heavy-duty crane runways, ground rail systems, and industrial tracks where stable, continuous support is required. Compared with individual rubber rail pads, the MK7 model uses a continuous elastomer strip reinforced with high-strength steel, delivering superior vibration damping, improved load distribution, and long-term performance in high-demand environments such as ports, shipyards, steel plants, coking plants, cement factories, and other industrial facilities.

Glory Track supplies the MK7 pad in two material options—SBR (styrene-butadiene rubber) and NBR (nitrile rubber)—to accommodate different oil-resistance levels, temperature conditions, and mechanical performance requirements.

MK7 Continuous Rail Pad Dimensions

The MK7 rail rubber pads are available in multiple sizes to fit different rail types and load requirements. Ensure the supporting soleplate matches the pad’s corresponding width dimension shown in the table below.

| TYPE | WIDTH (W mm) |

|---|---|

| MK7-098 | 98 |

| MK7-118 | 118 |

| MK7-128 | 128 |

| MK7-134 | 134 |

| MK7-147 | 147 |

| MK7-157 | 157 |

| MK7-168 | 168 |

| MK7-195 | 195 |

| MK7-215 | 215 |

MK7 Continuous Rail Pad material

Our MK7 continuous rail pads are engineered for heavy-duty crane runways and ground rail systems, combining reinforced elastomer construction with superior vibration and noise reduction performance.

| Specifications | SBR Continuous Rail Pad | NBR Continuous Rail Pad |

|---|---|---|

| Material | SBR (Styrene-Butadiene Rubber) | Nitrile Rubber (NBR) |

| Shore Hardness | 75–80 | 75 ± 5 |

| Maximum Tensile Strength | 27.3 MPa | 12.7 N/mm² |

| Elongation | ≥285% | 255% (200% after aging) |

| Working Temperature | –25°C to +100°C | –25°C to +100°C |

| Vibration Reduction | 40%–50% | 45%–50% |

| Noise Reduction | ≥10% | 12% (dBA) |

| Permanent Set | <20% | <5% (<20% after aging) |

| Available Lengths | 12 m | 12 m |

MK7 Rail rubber Pad Key Features

- 1. High-Performance Elastomer Options(SBR / NBR)

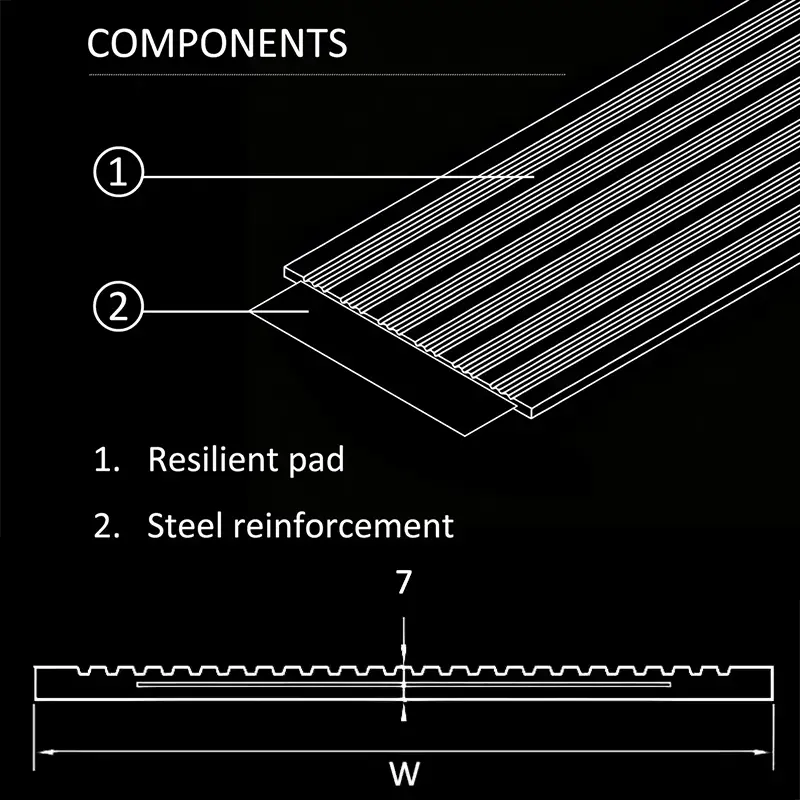

SBR offers strong wear resistance and excellent compression recovery for general crane runway applications. NBR provides enhanced oil resistance, oxidation stability, and durability under continuous heavy loading. - 2. Steel-Reinforced Structure for Stable Rail Support

A continuous steel strip is embedded inside the pad to increase lateral stiffness and maintain alignment under crane wheel loads. The strip is surface-treated before vulcanization, ensuring a strong bond with the rubber and preventing delamination during long-term service. - 3. Grooved Surface for Improved Contact

The engineered grooves increase friction between the rail and the pad, helping reduce micro-movement and wear. This design maintains consistent support and improves the stability of the entire crane rail system. - 4. Effective Noise & Vibration Reduction

The elastomer compound absorbs shock and smooths out irregularities between the rail and the steel support, lowering vibration and operational noise. This helps extend the service life of rails, wheels, axles, and related components. - 5. Durable in Harsh Industrial Environments

The MK7 pad resists water, oil, grease, UV exposure, and ozone—making it more reliable than standard rubber rail pads used in ports, shipyards, and heavy manufacturing plants.

Continuous Rail Pad Installation Instructions

Installation guidelines:

1.Insert bolt(s) through hole(s) in rail supporting structure.

2.Before installing rubber pad, the suppporting area should be clean and free oil; Laying the rubber pads on the support.

3.Intall the rails on the rubber pads.

4.Place body of clip over bolt(s) with rubber ‘nose’ resting on uppersurface of bottom flange of rail; Move clip into metal-to-metal contact with bottom edge of rail. Bottom face of clip will not be in full contact with rail support. Place special washer(s) over bolt(s); Tighten nut(s) with spanner;

With hammer of about 1 kilo, tap clip body towards rail alongTighten nut(s) to required torque given on product datasheet.direction of slot(s) in clip.

Notes:

Pad Width:The pad should be 5 mm narrower than the supporting rail.

Length:Supplied in 12-meter rolls; it can be cut using a hacksaw or jigsaw.

Minimum Installed Length:No installed segment should be shorter than the spacing across three pairs of crane rail clips.

Surface Preparation:The support surface must be clean, free of oil, grease, and sharp projections. It is recommended not to paint the steel structure before installation.

Grooves Upwards:Install the pad with the grooved surface facing upward.

Welding Precautions:If the rail is welded on-site, shield the pad from excessive heat or temporarily remove the section being welded.

Get Your Custom Quote

Glory Track supplies MK7 continuous rail pads engineered for demanding crane runway and ground rail systems. Contact us for technical guidance or a customized quotation for your project.