WJK QU100 Rail Clamp

The WJK QU100 Rail Clamp, also known as a welded rail clip or crane rail fixing system, is a standard fastening component designed for industrial crane beam tracks.

This model is specifically engineered for QU100 crane rails, combining a welded steel base with a precision bolt and wedge assembly to deliver a secure and durable rail fixing solution.

With robust mechanical strength and easy installation, the WJK QU100 rail clamp ensures reliable performance for heavy-duty cranes, gantry cranes, and shipyard applications.

Features of WJK QU100 Rail Clamp

- High Load and Lateral Resistance

When equipped with a Q345 base and Grade 8.8 bolts, the clamp can withstand a maximum lateral force of 55 kN, ensuring rail stability during heavy crane operation. - Durable Material and Precision Casting

Main components such as the press plate, welded base, and wedge adjustment plate are made from Q235 or Q345 cast steel, produced by investment casting and annealing for excellent internal strength and mechanical reliability. - Easy Installation and Adjustment

Designed for on-site efficiency, the wedge-type adjusting plate allows fine alignment of the clamp. Once the rail flange is secured, tightening the nut completes the installation quickly and safely. - Custom Engineering Options

Customized versions—such as reduced-height models—are available to suit restricted installation spaces or special operating conditions.

WJK QU100 Rail Clamp Spec

| Parameter | Details |

|---|---|

| Type | Rail Clamp / Rail Clip (Welded Fixing Type) |

| Model | WJK-QU100 |

| Applicable Rail | QU100 Crane Rail |

| Material | Q235 / Q345 cast steel |

| Matching Bolts | Grade 8.8 (for Q345 base) / Grade C (for Q235 base) |

| Washer Performance | 100 HV steel washer |

| Surface Tolerance | GB/T 6414-86M “Casting Size Tolerance” (CT6 level) |

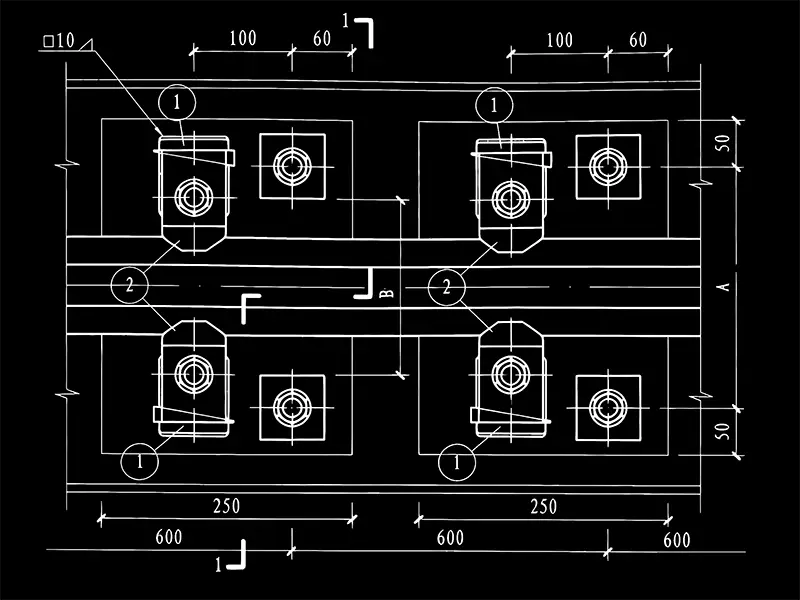

| Installation Spacing | Q < 275 t → 600 mm; Q > 275 t → 500 mm |

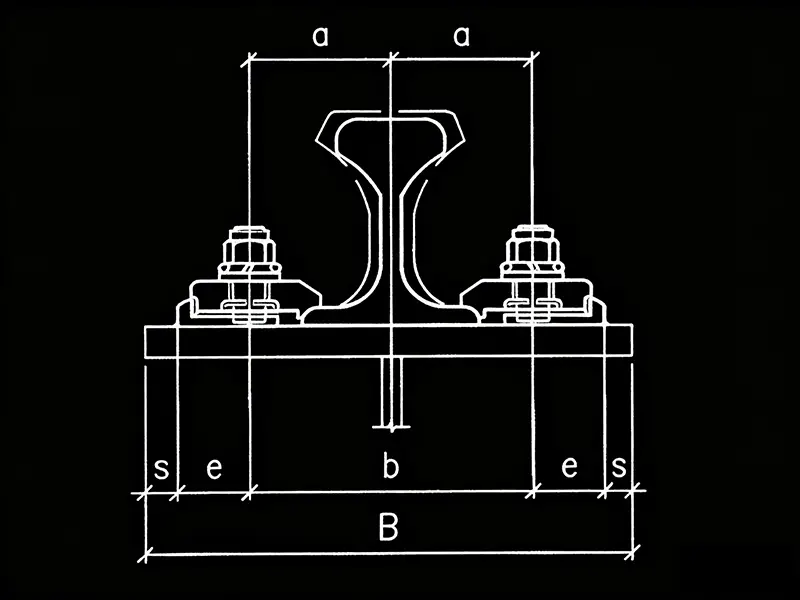

| Dimensions (mm) | a = 115, b = 230, e = 62 , 2e = 124 , s = 10 (5) , 2s = 20 (10) , B = 374 (364) |

Installation of WJK QU100 Rail Clamp

Preconditions:

Ensure the crane beam surface is leveled, painted, and all rail joints are properly aligned before installation.

Installation Steps:

- Weld the clamp base onto the embedded steel plate.

- Insert and position the T-bolt.

- Place the wedge adjustment plate (grooved side upward).

- Add the press plate, flat washer, spring washer, and nut in sequence.

- Adjust the wedge to align the rail precisely, then tighten the nut firmly.

Installation Spacing:

Install one pair of rail clamps on both sides of the rail every 500–600 mm, depending on crane load capacity.

Other series of crane rail clamps

Why Partner with Glory Track?

① liable Quality

Over 15 years of rail fastening expertise, proven in global crane, mining, and steel plant application

② Certified Manufacturing

Produced under ISO 9001 quality management with advanced machining and hardness testing.

③ Engineering Support

We provide drawing verification, on-site guidance, and tailored fastening solutions for your beam and rail profiles.

Get Your Custom Quote

Contact Glory Track today — we’ll provide a technical consultation and quotation within 24 hours.