Understanding Crane Rail Joint Welding

Crane rail joint welding is the process of joining two rail ends on a crane runway beam to create a continuous, stable, and high-strength track.

Compared to bolted joints, welded joints provide smoother trolley movement, reduce vibration and noise, and minimize wear on the crane wheels and rails.

For heavy-duty cranes, this joint integrity directly affects load stability and track alignment—making precise manual arc welding (SMAW) the preferred method.

Controlling Deformation During Welding

During the manual arc welding process, heat input causes the rail joint to bend downward.

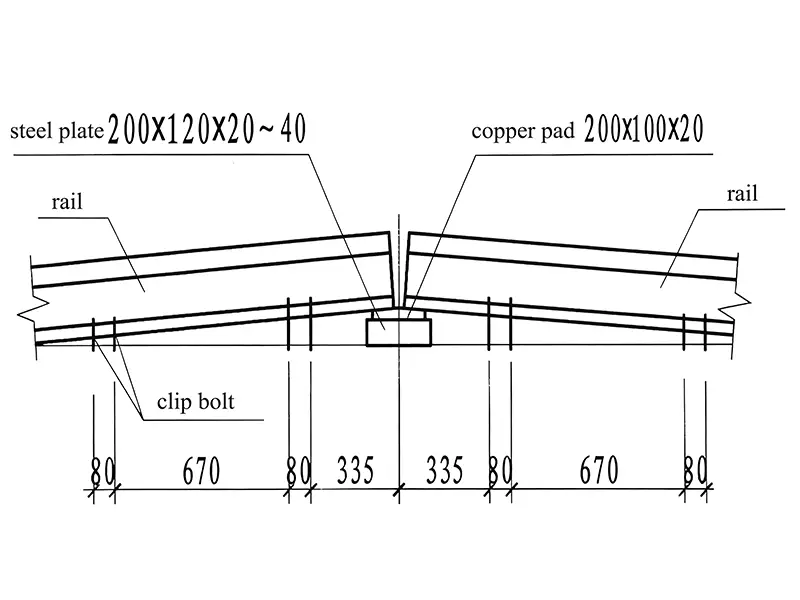

To maintain straight alignment after cooling, both crane rail ends must be elevated by 40–60 mm before welding. This is achieved using copper and steel shims, bolts, and clamps to fix the rail on the crane beam securely. The following diagram shows the setup for rail end elevation and clamping to prevent downward bending during welding.

Adjustment procedure:

- After welding the rail base, reduce elevation to about 20 mm.

- Once the rail web is welded, remove all shims.

- Throughout the process, regularly check straightness using a steel straightedge, adjusting clamp tension and elevation as needed.

The rail gap should be 12–14 mm (slightly narrower at the bottom).

Both ends must align precisely—no twist, offset, or lateral shift is acceptable. Misalignment during welding often leads to long-term crane track deviation or wheel flange wear.

Preheating and Tempering Process

Preheating and post-weld tempering are critical steps in crane rail joint welding, especially for outdoor or low-temperature conditions.

Uniform heating helps relieve stress, prevent cracks, and improve weld toughness under cyclic crane loads.

Typical parameters:

- Preheating range: 20–30 mm on each rail end

- Preheating temperature: approx. 250°C

- Tempering range: 40 mm from weld center each side

- Tempering temperature: 600–700°C

Use a gas torch to evenly heat the rail head, web, and base.

When thermometers are not available, welders can rely on the metal’s dull red glow as a visual cue of correct temperature.

After tempering, wrap the weld area with asbestos-insulated boxes to ensure slow, uniform cooling—this prevents hardening and internal stress.

Manual Arc Welding Procedure

Crane rail joints are typically welded using the Shielded Metal Arc Welding (SMAW) process.

Each joint requires coordination between one arc welder and one slag cleaner, with a gas welder assisting for preheating and tempering.

Welding sequence:

- Rail base (bottom) → first weld layer (180–200 A) for deep penetration

- Rail web (middle) → 160–180 A, upward welding direction

- Rail head (top) → 150–170 A, finishing layers and reinforcement

- Final touch-up and defect repair

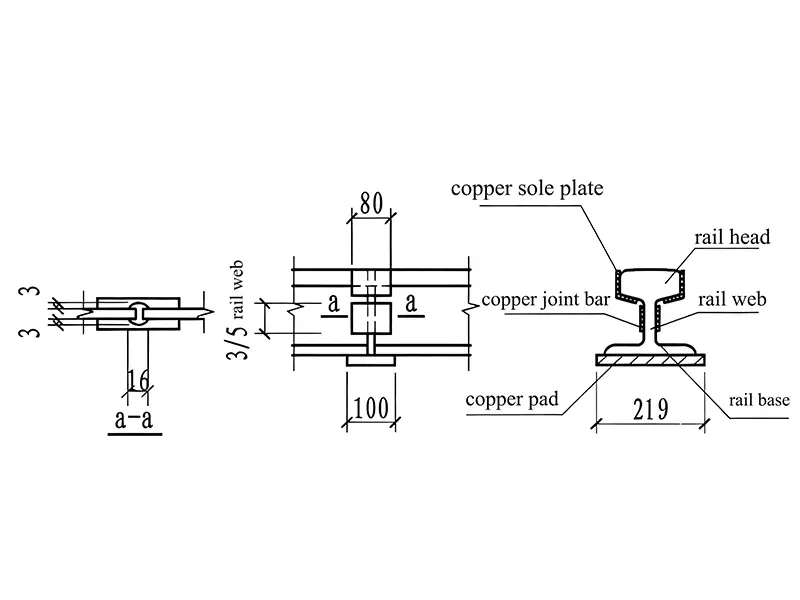

The diagram below illustrates the use of copper backing pads and joint bars during base and web welding of crane rails.

Use low-hydrogen electrodes (E7516 / E8516, GB/T5117–5118) on DC reverse polarity to ensure high toughness and crack resistance.

After each weld pass, thoroughly remove slag. Reuse the copper backing plates only after cooling and cleaning.

If welding is interrupted for a long time, preheating must be repeated before resuming.

In winter conditions, prevent rapid cooling or contact with moisture before the weld fully stabilizes.

Post-Weld Grinding and Alignment

Once the crane rail joint cools to ambient temperature, surface finishing begins.

The goal is to restore a perfectly smooth top running surface for the crane wheel to pass over without impact.

- Roughly remove excessive weld metal using a chisel.

- Follow with a grinding wheel until flush with the rail head.

- Finish by fine sanding or filing to eliminate ridges or deep marks.

Proper rail joint grinding ensures seamless trolley movement, reduces dynamic stress, and extends the life of both the rail and the crane wheel.

Best Practices for Crane Rail Joint Welding

To guarantee reliable and durable welded joints:

- Maintain even heating across the full rail cross-section.

- Monitor deformation throughout the welding process.

- Use certified low-hydrogen electrodes and keep them dry.

- Perform continuous welding to retain thermal uniformity.

- Grind and inspect every joint to ensure smoothness and alignment.

Conclusion

Effective crane rail joint welding using the manual arc welding method (SMAW) requires precision, coordination, and temperature control.

By mastering deformation management, heat treatment, and grinding techniques, you can achieve smooth, durable crane rail connections that stand up to heavy loads and continuous operation.

For reliable crane rail welding and installation support, contact Glory Track—your trusted partner in crane runway rail systems and steelwork fabrication.